Antenocitis Workshop addresses the second issue by including a detail card for the end-caps. This glues in place and ensures that the nooks and crannies have detailing that is thematically similar to the rest of the model.

These thin cards are easily attached with tacky glue or Super-Phatic (very thin, strong, PVA). I clamp them in place for a few minutes to ensure a strong bond.

Here is a "before" shot showing the plain end-caps. Since the MDF is pre-painted it actually looks fine as it is... but its gonna be so much better after!

To the right the end-caps have been installed and the detailing is very nice. You will notice a difference in color between the edges of the end-caps and the base MDF. This is easily sorted later with a quick touch-up pass using Nut Brown (Reaper) paint.

Clamping up the rest of the assembled shell.

The remaining bits. The two topmost thin strips that we were careful not to glue into place during the build, the roof/lid, and the end-caps for them. Its best to wait to install the end-caps for these parts until after the resin goes in. For the most part they work if the ends are aligned but small differences in the shell construction can be adjusted for in the final fit of these.

Moving on to the remaining resin. Some of the resin was installed earlier in "part 1". To the left is what remains. (There is one extra locker shown as I was touching up a part from a previous Hab 3).

The large bunk wall usually requires a hot water bath to adjust for warping. This is likely due to the big hole in it for the bunk assembly. Its easy to straighten and when the bunk is attached to the wall it reinforces the shape nicely.

At this point all the remaining resin gets pre-fitted, sanded as required to adjust the fit and then painted. These are often a very tight fit that should be adjusted via sanding the edges of the resin bits until they fit snugly but don't require force to get into position. Keep in mind that the height of the resin will also likely need to be adjusted to be level with the top of the MDF. I failed to notice that during this build and the top retaining strips were very tricky to get installed.

The pre-fit of these parts is critical and should not be skipped.

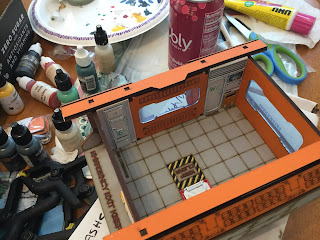

The painted walls can now be slid into place. I align them using the printed floor graphics.

Antenocitis Workshop really excels at minute details and photographic elements like video screens etc. All the graphic elements here are from them except the tabletop which is repurposed from some hobby packaging.

Once the interior resin is in place the Topmost strips are finally glued into position and the remaining end-caps can be installed.

Test fit the roof/lid for alignment mark with pencil and glue in the lid end-caps. There can be some variation so be careful to get the alignment right before gluing these in place. Carefully trim the overhang, if any, with a sharp hobby knife.

Now its touch up time. Go round the whole model with Nut Brown and toch up the spots where the MDF shows bare... like where it was previously attached to the frame etc...

A "in progress" view to the right. you can clearly see the difference between the touched up end caps and those not touched up.

All that remains for "part 3" are the exterior acrylic lights... which are a tiny bit tricksey..., the interior/exterior scatter, and the lower "feet" which are unique to Hab 3 and help it interlock when stacking with other buildings in the series (specifically Habitat 1 or Habitat 4) and should not be installed until their companion buildings top lugs have been installed to make sure they line up properly.

Part 3 will be a bit coming as I'll want to finish this after building Habitat 1 or 4...

Cheers

No comments:

Post a Comment